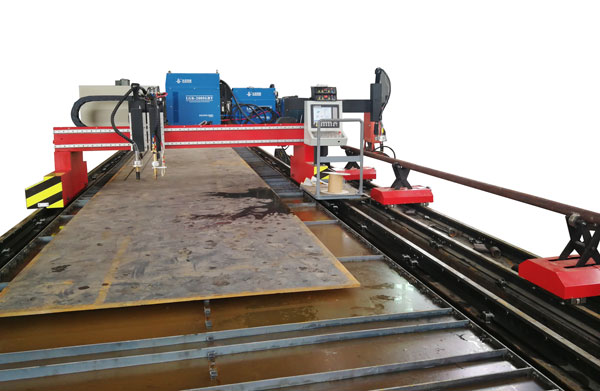

Well-designed Koike Plasma Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar

Well-designed Koike Plasma Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar Detail:

Features

- The whole machine adopts the welded steel plate welded structure. The beam is cut by laser cutting and then welded together. The upper and lower sides of the beam are bent by 90 degrees with the steel plate, which can reduce the deformation and increase the rigidity.

- The beam hanging plate is welded with 20mm steel plate, and the whole surface is processed by gantry planer to reduce the deformation of the whole surface and improve the precision.

- After the whole machine is welded, firstly, the aging treatment is performed after stress aging, followed by the surface rust removal treatment. After the primer is applied, the surface is painted.

Technical parameter

| Model | MS-4GB-3280 | MS-4GB-3212 | MS-4GB-4080 | MS-4GB-4012 |

| Overall size | 3200×8000 | 3200×12000 | 4000 x 8000 | 4000×12000 |

| Effective cutting range | 2300 x 6000mm | 2300 x 10000mm | 3000 x 6000mm | 3000 x 10000mm |

| Round tube cutting length | 6000mm | 12000mm | 8000mm | 12000mm |

| Cutting tube diameter |

Φ50-500mm (can be customized according to customer requirements) |

|||

| Operating accuracy |

0.2mm/m |

|||

| Pip bearing weight |

≤1500KG |

2000KG |

||

| Numerical control linkage number |

3-axis 2 linkage |

|||

| Number of supports | 3 sets | 4 sets | 3 sets | 4 sets |

| Tube ellipticity |

≤2% |

|||

| Cutting type |

tandard: flame + plasma dual-purpose cutting (can be customized) |

|||

| transfer method |

Gear rack drive |

|||

| Torch lift |

≤160mm |

|||

| Flame cutting thickness |

Piercing thickness: 5-60mm Edge cutting thickness: 5-200mm |

|||

| Plasma cutting thickness |

According to the size of the plasma power supply |

|||

| Gas supprfy requirements |

Acetylene / propane gas pressure ≤0.1 MP |

|||

| Oxygen supply requirements |

Oxygen maximum pressure ≤1MP |

|||

| Cutting table infrastructure |

We will provide the gantry cutting table drawing for the user reference (basic equipment and H-beam by the customer to buy) |

|||

Cutting Sample

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for Well-designed Koike Plasma Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar , The product will supply to all over the world, such as: Swiss, Grenada, Sao Paulo, With more and more Chinese products around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to offer you both better products and service, because we are more and more powerful, professional and experience in domestic and international.

We have been looking for a professional and responsible supplier, and now we find it.

Write your message here and send it to us