Short Lead Time for Plasma Pipe Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar

Short Lead Time for Plasma Pipe Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar Detail:

Features

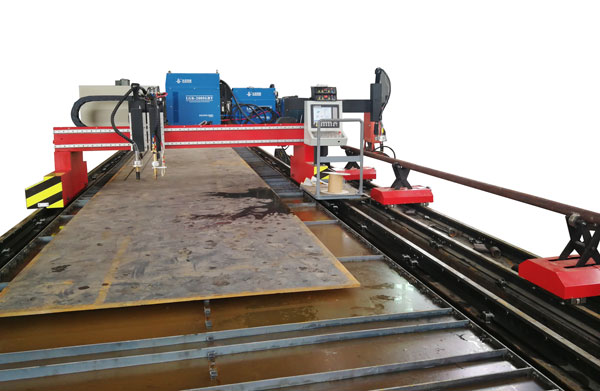

- The whole machine adopts the welded steel plate welded structure. The beam is cut by laser cutting and then welded together. The upper and lower sides of the beam are bent by 90 degrees with the steel plate, which can reduce the deformation and increase the rigidity.

- The beam hanging plate is welded with 20mm steel plate, and the whole surface is processed by gantry planer to reduce the deformation of the whole surface and improve the precision.

- After the whole machine is welded, firstly, the aging treatment is performed after stress aging, followed by the surface rust removal treatment. After the primer is applied, the surface is painted.

Technical parameter

| Model | MS-4GB-3280 | MS-4GB-3212 | MS-4GB-4080 | MS-4GB-4012 |

| Overall size | 3200×8000 | 3200×12000 | 4000 x 8000 | 4000×12000 |

| Effective cutting range | 2300 x 6000mm | 2300 x 10000mm | 3000 x 6000mm | 3000 x 10000mm |

| Round tube cutting length | 6000mm | 12000mm | 8000mm | 12000mm |

| Cutting tube diameter |

Φ50-500mm (can be customized according to customer requirements) |

|||

| Operating accuracy |

0.2mm/m |

|||

| Pip bearing weight |

≤1500KG |

2000KG |

||

| Numerical control linkage number |

3-axis 2 linkage |

|||

| Number of supports | 3 sets | 4 sets | 3 sets | 4 sets |

| Tube ellipticity |

≤2% |

|||

| Cutting type |

tandard: flame + plasma dual-purpose cutting (can be customized) |

|||

| transfer method |

Gear rack drive |

|||

| Torch lift |

≤160mm |

|||

| Flame cutting thickness |

Piercing thickness: 5-60mm Edge cutting thickness: 5-200mm |

|||

| Plasma cutting thickness |

According to the size of the plasma power supply |

|||

| Gas supprfy requirements |

Acetylene / propane gas pressure ≤0.1 MP |

|||

| Oxygen supply requirements |

Oxygen maximum pressure ≤1MP |

|||

| Cutting table infrastructure |

We will provide the gantry cutting table drawing for the user reference (basic equipment and H-beam by the customer to buy) |

|||

Cutting Sample

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for Short Lead Time for Plasma Pipe Cutting Machine - Gantry Pipe and Plate integrated cutting machine – Meisar , The product will supply to all over the world, such as: Iraq, Iran, Angola, With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Write your message here and send it to us