Professional Design Plasma Stainless Steel Cutting - CNC fine plasma cutting machine MS-4C – Meisar

Professional Design Plasma Stainless Steel Cutting - CNC fine plasma cutting machine MS-4C – Meisar Detail:

Technical parameter

| Model | MS-4C(4012) | MS-4C(4012) |

| Effective cutting range | 3000mm x 10000mm | 3000mm x 10000mm |

| CNC system | EXC880 | ICNCXT |

| Input voltage | AV-220VSingle phase AV-220V | AV-220V Single phase AV-220V |

| input power | 3200W | 3200W |

| Running speed | 0-15000mm/min | 0-15000mm/min |

| Torch lift | ≤160mm | ≤160mm |

| Operating accuracy | 0.2mm/m | 0.2mm/m |

| Longitudinal track/rack | Fine grinding 55KG/M track / fine grinding helical tooth | |

| Plasma cutting thickness | According to the size of the plasma power supply | |

Features

The perfect mechanical structure, ultra-high standard processing technology and strict quality management have created the highest level of plasma cutting machine.

The CNC fine plasma cutting machine is the finest plasma power supply with the most high-precision CNC machine tool and the most advanced technology in the world. It not only has the characteristics of the current ordinary plasma cutting machine, but also has the following characteristics:

1/Surface cutting roughness Ra ≤ 13 Cutting verticality ≤ 2 degrees, surface cutting quality reaches the lower limit of laser cutting quality.

2/Cutting size accuracy is more than double that of ordinary plasma.

3/The slit width is about 1/2 of that of ordinary plasma.

4/ Cutting medium plate speed is higher than laser and ordinary plasma.

5 / electrode / nozzle life, far more than ordinary plasma, about 5 times more than ordinary plasma.

6/ Equipment investment cost and operating cost are only 1/3-1/9 of laser laser.

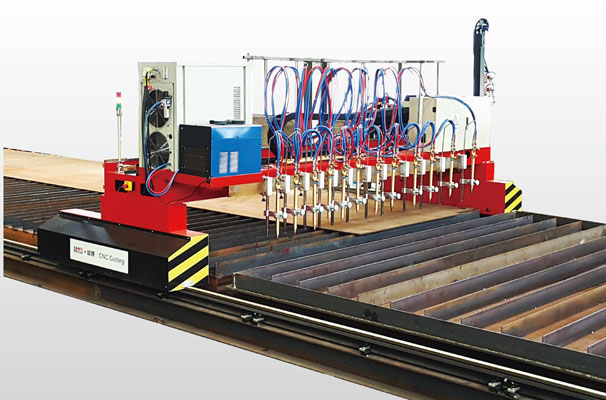

Customer use site

Cutting Sample

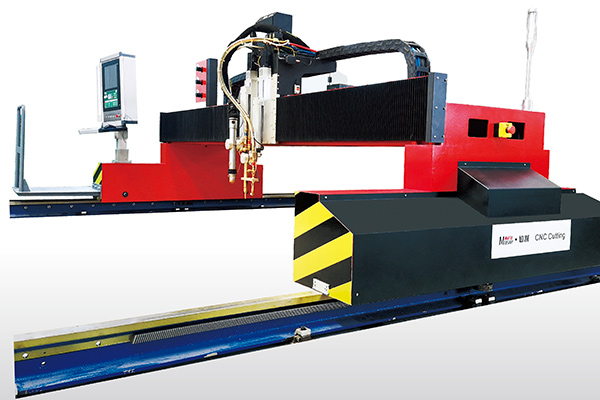

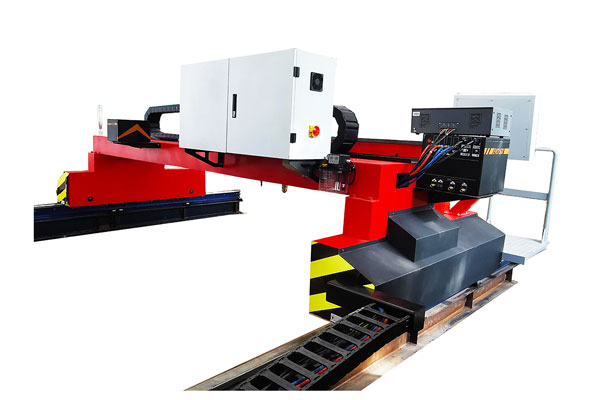

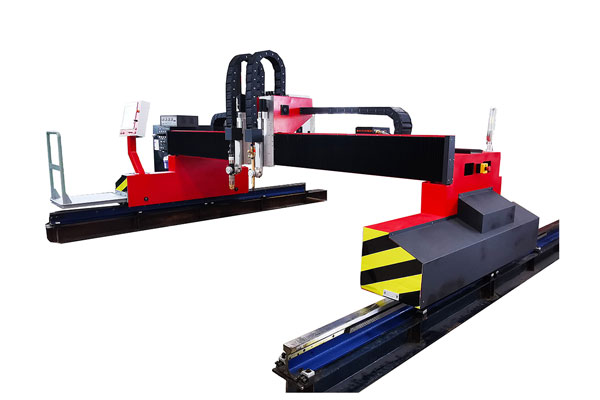

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Professional Design Plasma Stainless Steel Cutting - CNC fine plasma cutting machine MS-4C – Meisar , The product will supply to all over the world, such as: Melbourne, Algeria, Las Vegas, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.