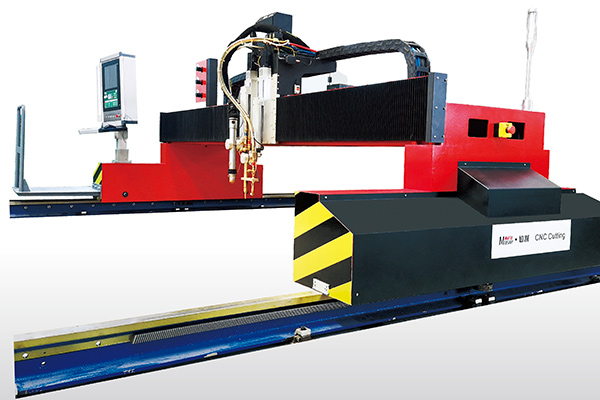

OEM Customized Cnc Plasma Cutting System - Gantry CNC flame&plasma cutting machine – Meisar

OEM Customized Cnc Plasma Cutting System - Gantry CNC flame&plasma cutting machine – Meisar Detail:

Features

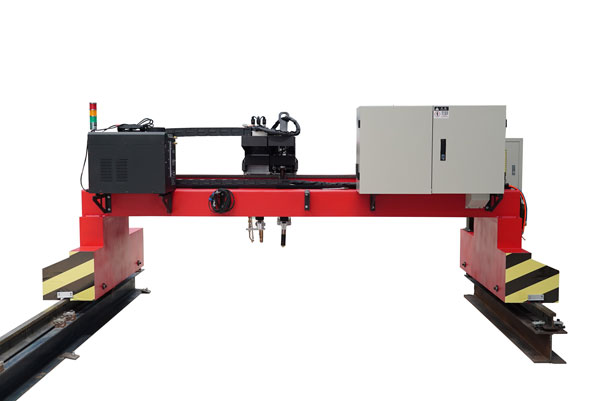

- The whole machine adopts the welded steel plate welded structure. The beam is cut by laser cutting and then welded together. The upper and lower sides of the beam are bent by 90 degrees with the steel plate, which can reduce the deformation and increase the rigidity.

- The beam hanging plate is welded with 20mm steel plate, and the whole surface is processed by gantry planer to reduce the deformation of the whole surface and improve the precision.

- After the whole machine is welded, firstly, the aging treatment is performed after stress aging, followed by the surface rust removal treatment. After the primer is applied, the surface is painted.

Technical parameter

| Model | MS-4B (4080) | MS-4B (5012) | MS-4B (6012) | MS-4B (7012) |

| Machine structure |

Laser cutting, steel plate welding structure with heat treatment |

|||

| Effective cutting range(X/Y) | 3000 x 6000mm | 4000 x 10000mm | 5000 x 10000mm | 6000 x 10000mm |

| Lateral rail spacing | 4000mm | 5000mm | 6000mm | 7000mm |

| Longitudinal guide length | 8000mm | 12000mm | 12000mm | 12000mm |

| The number of lifts |

Standard for the double moving lift device |

|||

| Input voltage |

AV-220V Single phase AV-220V |

|||

| input power |

About 2500W |

About 3000W |

||

| Running speed |

0-10000mm/min |

|||

| Cutting type |

1, plasma cutting (with plasma power) 2, flame cutting 3, flame + plasma cutting |

|||

| Torch lift |

≤160mm |

|||

| Operating accuracy |

0.2mm/m |

|||

| Flame cutting thickness |

Piercing thickness: 5-60mm Edge cutting thickness: 5-200mm |

|||

| Plasma cutting thickness |

According to the size of the plasma power supply |

|||

| Flame automatic Ignition device |

With flame automatic ignition device function |

|||

Customer use site

Cutting Sample

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

In an effort to provide you advantage and enlarge our business enterprise, we even have inspectors in QC Staff and assure you our greatest provider and item for OEM Customized Cnc Plasma Cutting System - Gantry CNC flame&plasma cutting machine – Meisar , The product will supply to all over the world, such as: UK, Kenya, Hungary, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

Write your message here and send it to us