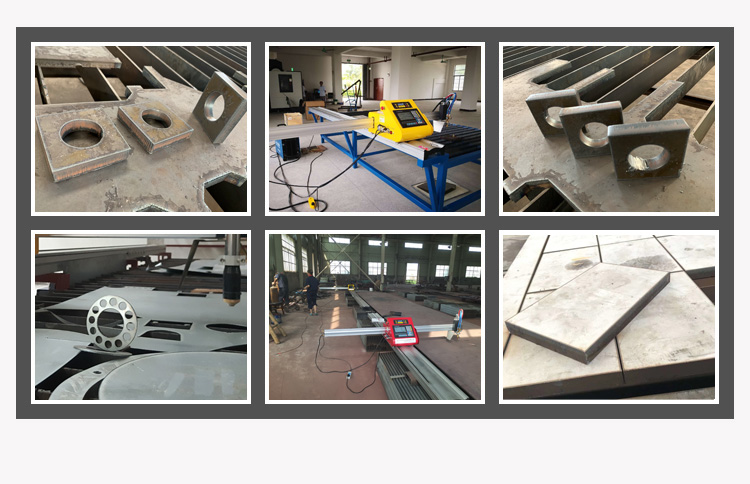

hot-portable-cnc-cutting-machine-flame-and-plasma-products

hot-portable-cnc-cutting-machine-flame-and-plasma-products,

hot-portable-cnc-cutting-machine-flame-and-plasma-products,

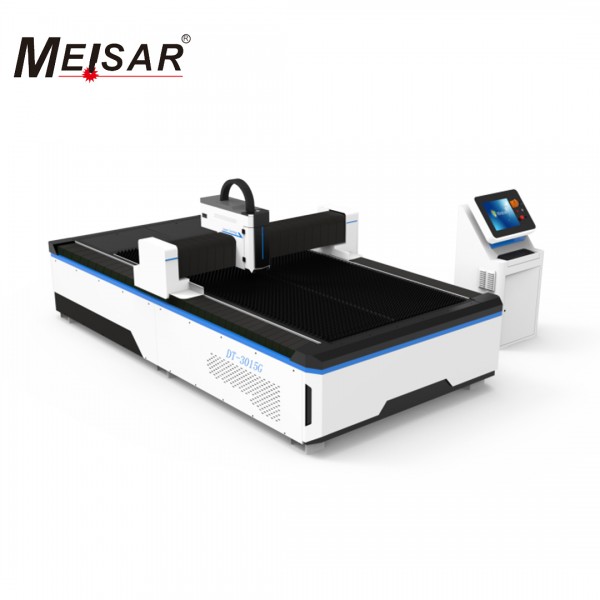

product description

Meisar CNC Technology Co., Ltd. carefully developed and developed a high-precision portable CNC flame / plasma cutting machine, its affordable, easy to use and easy to learn more accurate. Than the original cutting machine processing format larger, thicker cutting thickness. For wider,High strength, durable for a long time Effectively reduce processing costs. Machine covers an area of small, fully effective equipment to play the effectiveness.

Features

1, the new special high-strength hard aluminum alloy rails, the whole operation smooth and no noise, with high-speed high-precision and so on. 2, the whole operation is simple, full-featured, with man-machine dialogue and so on.

3, can be achieved CAD file into a working program file, automatic nesting function, through the U disk transmission to the transmission to The system mainframe cuts the metal material arbitrarily.

4, with portable CNC cutting machine function, for carbon steel, stainless steel and non-ferrous metal cutting.

5, with plasma flame plasma dual-use cutting function.

6, with Chinese, English, French, Russian and other languages.

7, the system has automatic power off memory and automatic recovery function.

8, increase the way: electric height and arc pressure automatically increase the two, the flame for the electric increase, the plasma for the arc pressure automatically raised, self-test plate Adjust the change and automatically increase the height of the torch and steel plate, to avoid cutting the gun hit the steel plate to reduce losses.

Technical Parameters

|

Name |

Portable CNC flame cutting machine |

|

|

Model |

MS-1530HDX |

|

|

Arc pressure increase |

No arc pressure adjustment device |

|

|

Cutting range (X * Y) |

1500*3000 |

|

|

Customizeinformation |

The length of the guide rail (effective cutting length Y axis) can be customized according to customer requirements |

|

|

Y-axis guide size |

3500*293*100 |

|

|

Motor type |

57 # stepper motor |

|

|

Torch raise type |

Electric up |

|

|

The number of lifts |

1set |

|

|

nput voltage |

Single phase AC-220V |

|

|

input power |

About 220W |

|

|

Running speed |

0-6000mm / min (max 8000mm / min) |

|

|

Cutting type |

Flame / plasma cutting |

|

|

Drive mode |

Gear rack drive |

|

|

Torch lift |

0-105mm |

|

|

Operating accuracy |

0.2mm/m |

|

|

Flame cuttingthickness |

Piercing ability:5-60mm edge cutting 5-150mm |

|

|

Plasma cuttinthickness |

Depending on the size of the plasma power supply |

|

|

Flame ignition device |

Standard with no (customizable) |

|

|

Gas requirements |

Acetylene / propane gas pressure ≤ 0.1MP |

|

|

Oxygen requirements |

Oxygen maximum pressure ≤ 1MP |

|

|

Selection of color |

Red, yellow and blue |

|

|

Cutting table |

We provide cutting table drawings for the user reference (materialrequired to purchase their own users) |

|