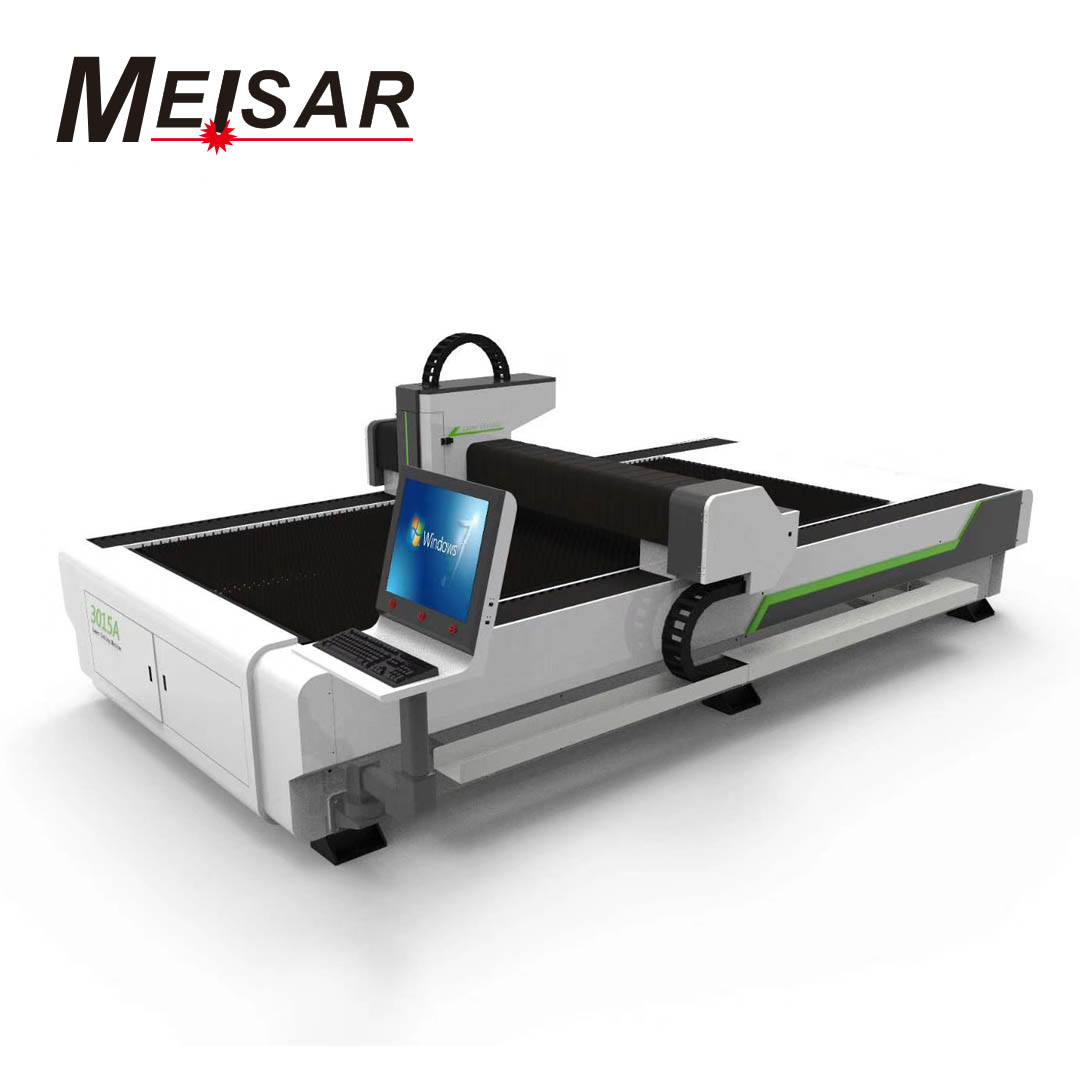

3015G Fiber Laser CNC Cutting Machine

Technical parameter

|

Model |

MS-3015 |

MS-4020 |

MS-6020 |

|

Working area (mm) |

3025mm x 1525mm |

4025mm x 2025mm |

6025mm*2025mm |

|

Maximum acceleration |

1.2G |

1.2G |

1.2G |

|

Maximum positioning speed |

80m/min |

80m/min |

80m/min |

|

Linkage speed |

100m/min |

100m/min |

100m/min |

|

positioning accuracy |

±0.03mm/m |

±0.03mm/m |

±0.03mm/m |

|

Repeatability |

0.03mm/m |

0.03mm/m |

0.03mm/m |

|

Machine tool weight |

≤ 5000KG |

≤ 7500KG |

≤ 9500KG |

|

Maximum load weight |

700KG |

1100KG |

1500KG |

Features

1.The professional laser cutting machine operating system can ensure the cutting quality, make the cutting work more convenient and the operation is simpler.

2.The machine tool is a gantry structure with good rigidity and can withstand high cutting speed and acceleration.

3.The fiber laser cutting machine adopts the imported AC servo system drive and imported transmission system, and imports linear guide rails to ensure high speed, high precision and high reliability of the equipment.

4. The rack and guide rail adopts full sealing protection and automatic refueling device to prevent oil-free friction movement and dust pollution, improve the service life of the transmission parts and ensure the accuracy of machine tool movement.

5. small footprint, system integration, easy operation and maintenance, to meet the needs of 24-hour industrial production.

Exchanging Platform:

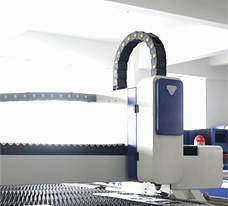

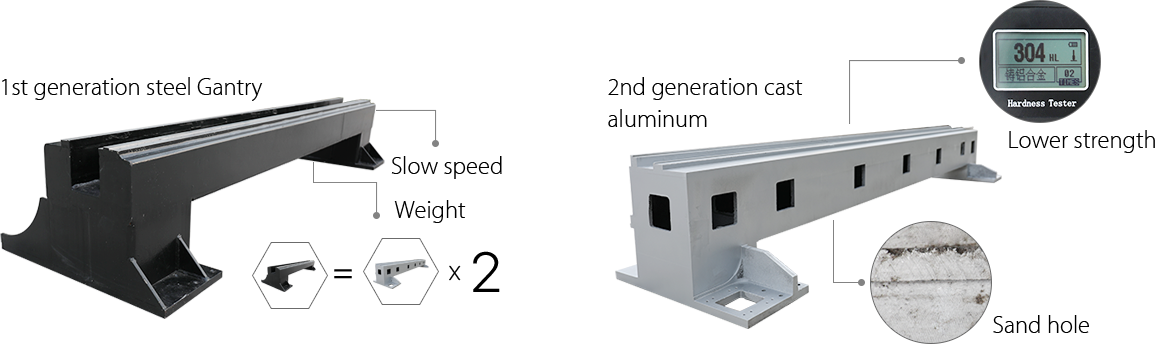

It adopts an up and down exchange platform; The converter is responsible for controlling the exchanging motor; The machine is able to finish the platform exchanging within 15s.The Third Generation Aviation Aluminum Gantry

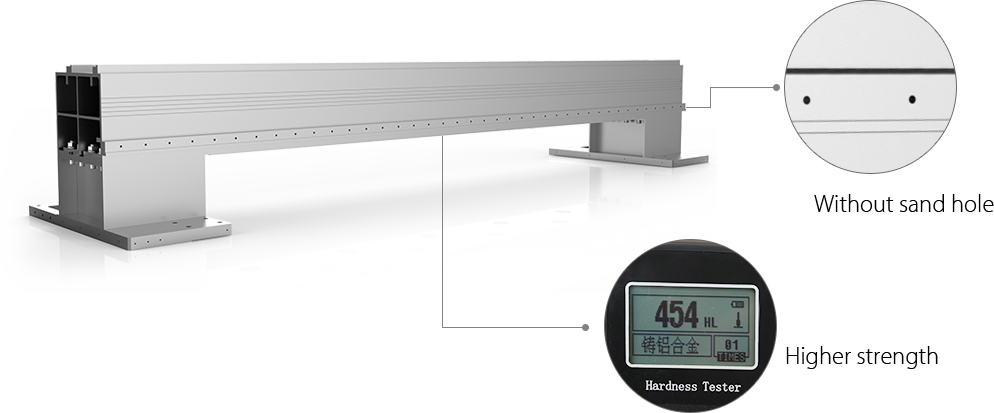

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries.

Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

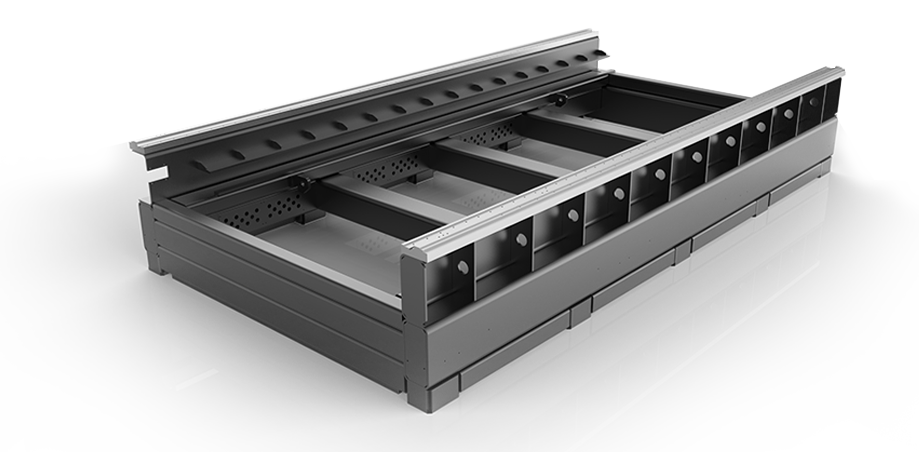

The Segmented Rectangular Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes.

Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

- High strength, stability, tensile strength, ensuring 20 years of use without distortion;

- Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

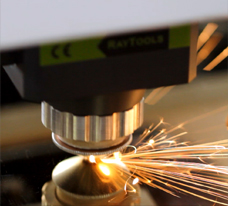

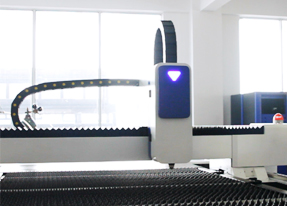

Laser cutting head, it can focus automatically

- Without manual focusingThe software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

- Bigger adjustment rangeAdjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

- Long service lifeCollimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Meisar fiber laser cutting machine is equipped with German Atlanta rack, Japanese Yaskawa motor and German Neugart reducer.

The positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 10 years.

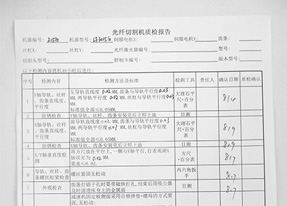

QUALITY MANAGEMENT SYSTEM

Meisar CNC is one of the biggest suppliers among cutting equipment in east China. Company mainly engage in CNC laser cutting machine, CNC plasma cutting machine, CNC Pipe/Tube cutting machine, etc. Meisar CNC has 14 years history, serving more than 80 countries and regions.

Meisar CNC has strict quality control system and quality management team. Strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer’s requirements.

Incoming Inspection

For every part of the machine, Meisar CNC is strictly control the quality.

Not only require suppliers to provide quality inspection reports, but also strict quality monitoring will be carried out when the parts are in the factory.

Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Meisar CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.

Pre-delivery Inspection

The machine will accept a number of quality testing, respectively, from the performance, stability, fit, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, To ensure that the final factory, the machine is in the best condition.