Fast delivery Cnc Plasma Torch Head - MS-1560T CNC Desktop Cutting Plasma Machine Series A – Meisar

Fast delivery Cnc Plasma Torch Head - MS-1560T CNC Desktop Cutting Plasma Machine Series A – Meisar Detail:

The machine configuration

1, the system has automatic bridge, the path to break up, add knife line, automatic positioning and other functions, support PLT, ENG, DXF, G code and other formats.

2, graphics can be any rotation, scaling, X / Y mirror, moments arranged, empty walk, and other functions. Support the processing of pause, forward, backward, high-speed and other functions.

3, automatic seam compensation, the original rail back, forward and other functions. The main features of the device – efficient: the fastest up to 15m / min Stability: the choice of high-quality high-quality components, the top core components. Energy saving: change the traditional backward technology, the equipment cutting workload With the workload of three workers in the workpiece, so as to save you cost.

4, only a few steps can achieve the purpose of cutting

Technical Parameters

| Name |

Industrial desktop CNC piasma cutting machine |

|||||

| Model | MS-1530T | MS-1540T | MS-1560T | MS-1530TX-SE | MS-1540T-SE | MS-1560TX-SE |

| Motor type |

Dual drive 86 # motor + planetary gear reducer |

Dual drive Panasonic servo motor + planetary gear unit |

||||

| Effective cutting range (X/Y) | 1500*3000 | 1500*4000 | 1500*6000 | 1500*3000 | 1500*4000 | 1500*6000 |

| Customize information |

Longitudinal rail length (Y axis) can be extended or shortened according to user requirements |

|||||

| Rail spacing | 2050mm | 2050mm | 2050mm | 2050mm | 2050mm | 2050mm |

| Rail length | 3850mm | 4350mm | 6800mm | 3850mm | 4350mm | 6800mm |

| Torch raise type |

1, plasma arc pressure increase 2, pneumatic control increased |

|||||

| Input voltage |

Single-phase AC-220V (soot cleaning equipment AC-380V) can be customized other voltage |

|||||

| input power |

About 1100W (dust purification equipment about 2200W) |

|||||

| Running speed |

0-10000mm/min |

0-10000mm/min |

||||

| Cutting type |

Plasma arc pressure adjustment Automatic cutting / plasma pneumatic adjustment cutting |

|||||

| Workpiece gas |

Compressed air (0.4Mpa-0.55Mpa) |

|||||

| Emergency stop switch |

Yes |

|||||

| Workpiece ambient temperature |

-5℃/50℃ |

|||||

| Relative humidity |

≤95%不凝结 |

|||||

| transfer method |

Gear rack drive |

|||||

| Torch lift |

≤ 150mm |

|||||

| Operating accuracy |

0.2mm/m |

|||||

| Plasma cutting thickness |

Depending on the size of the plasma power supply |

|||||

| Cutting table infrastructure |

Cutting the host for the one-piece structure, we provide the whole machine, no need to do material |

|||||

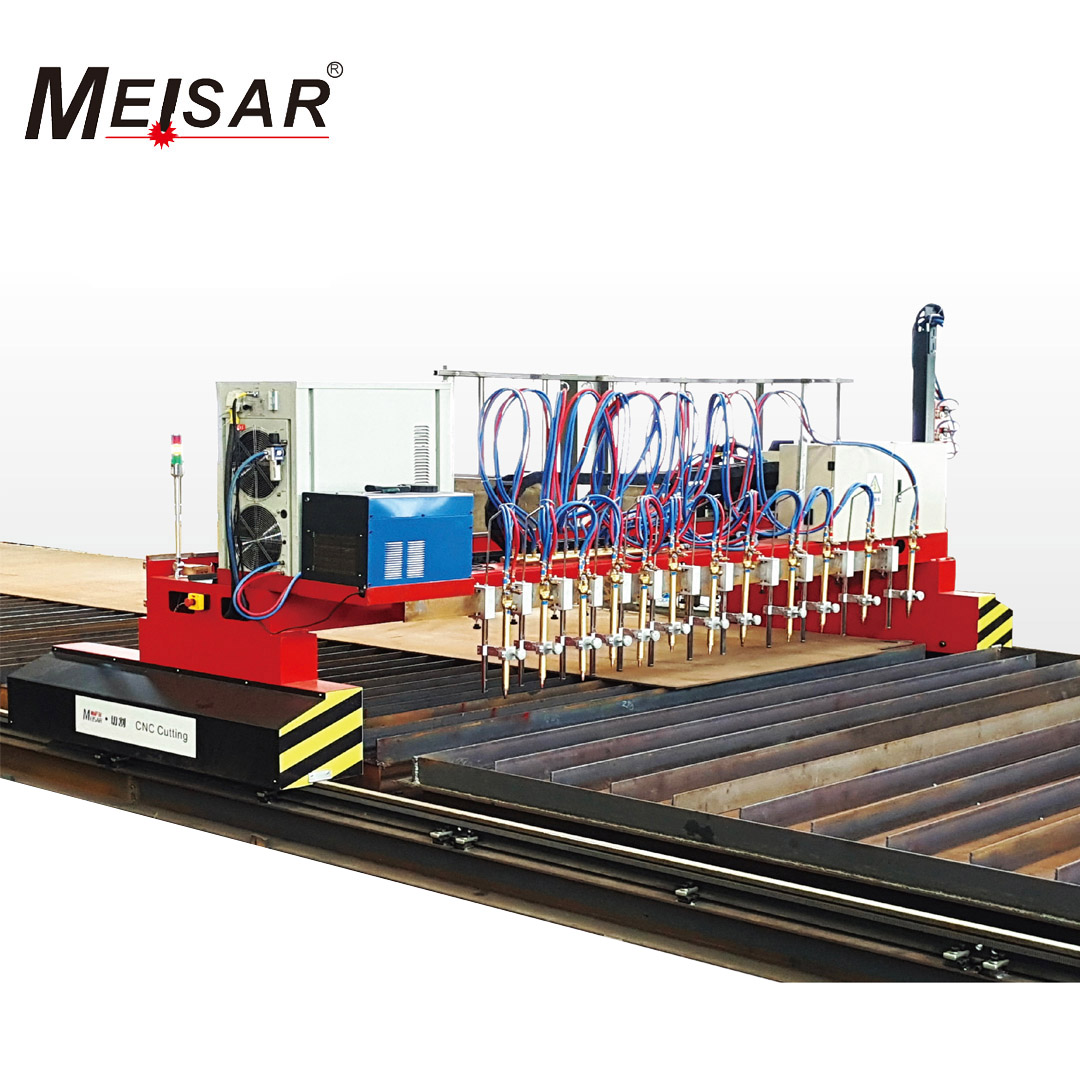

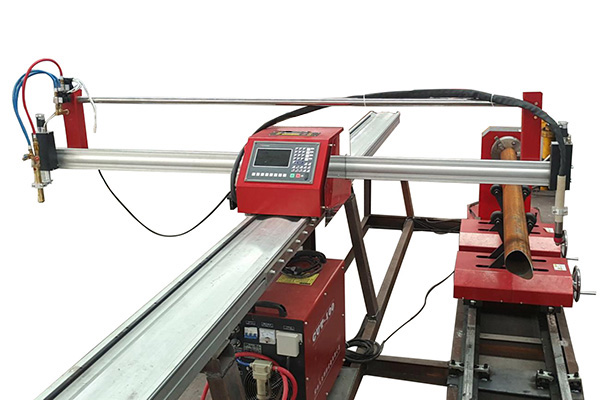

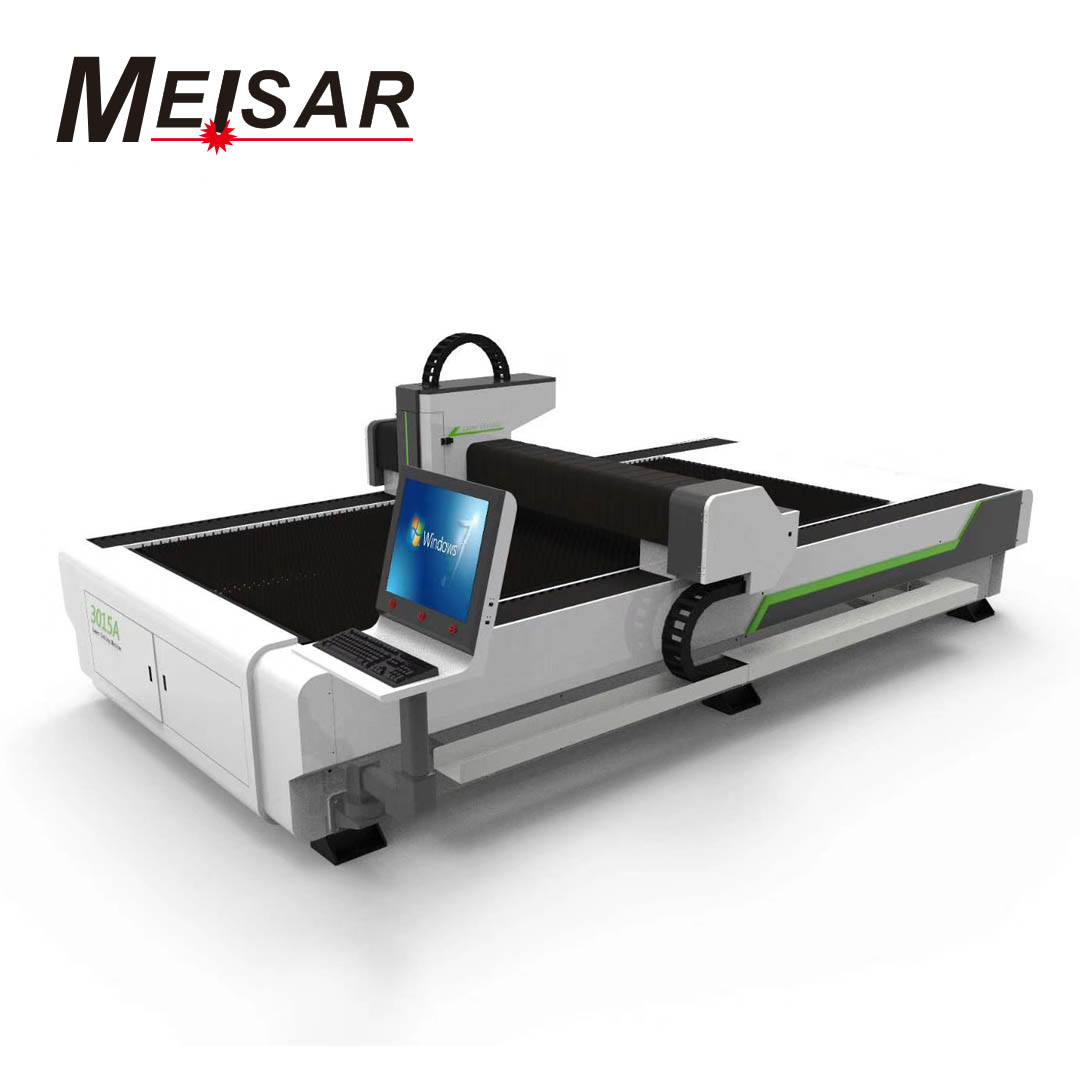

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for Fast delivery Cnc Plasma Torch Head - MS-1560T CNC Desktop Cutting Plasma Machine Series A – Meisar , The product will supply to all over the world, such as: Lithuania, Mozambique, Iceland, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.