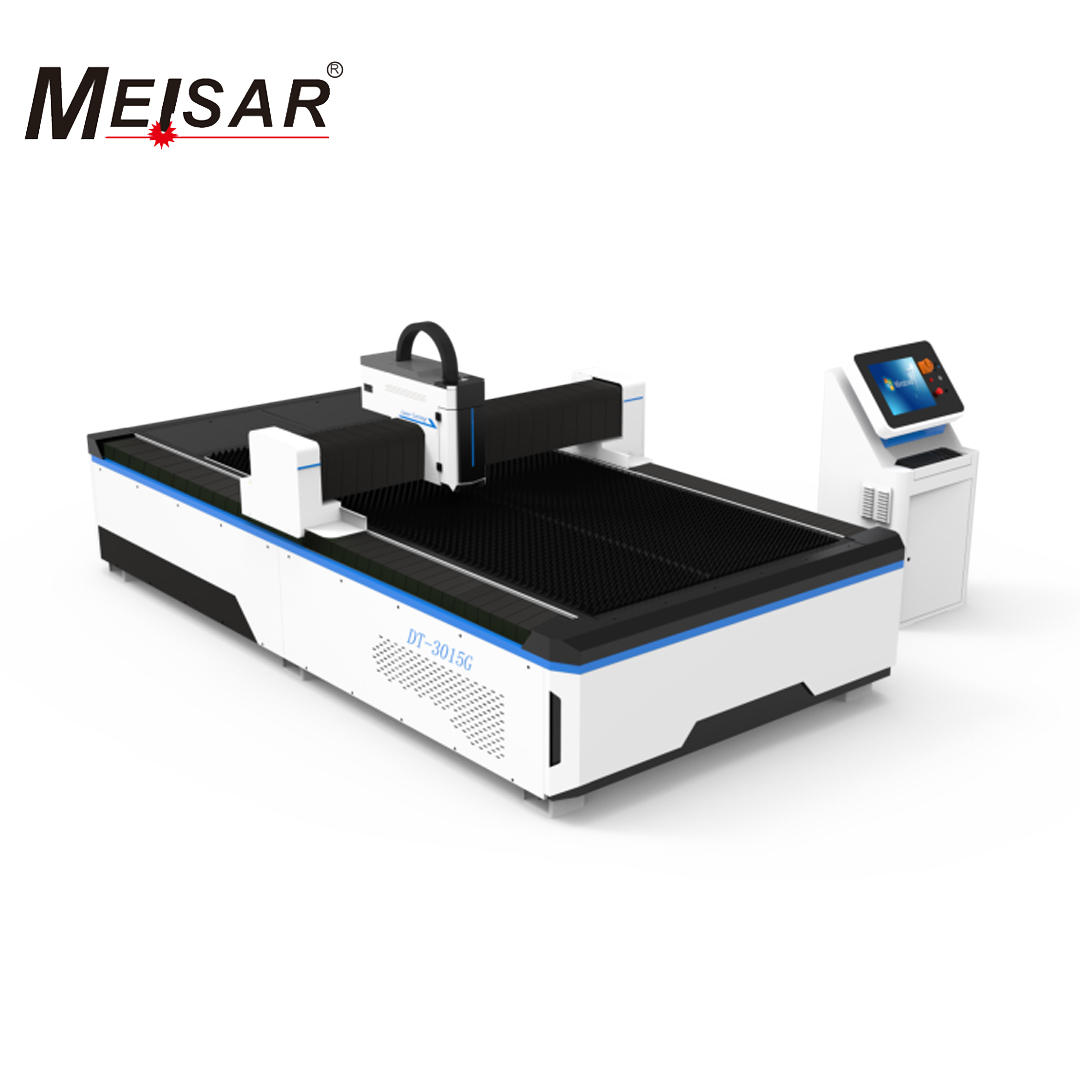

2019 High quality Plate Cutting - MS-4B (5012) Gantry CNC Plasma Cutting Machine – Meisar

2019 High quality Plate Cutting - MS-4B (5012) Gantry CNC Plasma Cutting Machine – Meisar Detail:

Features

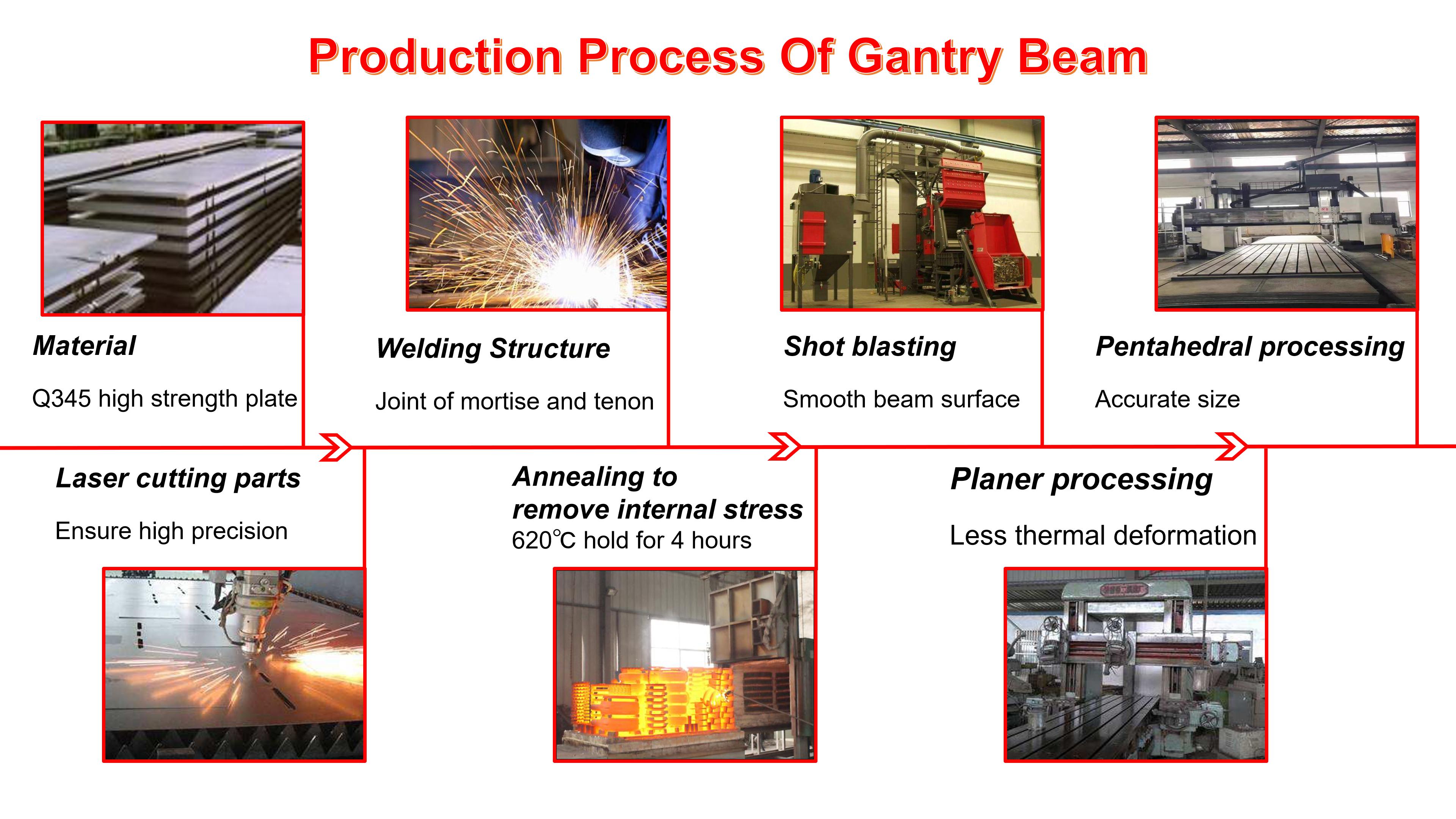

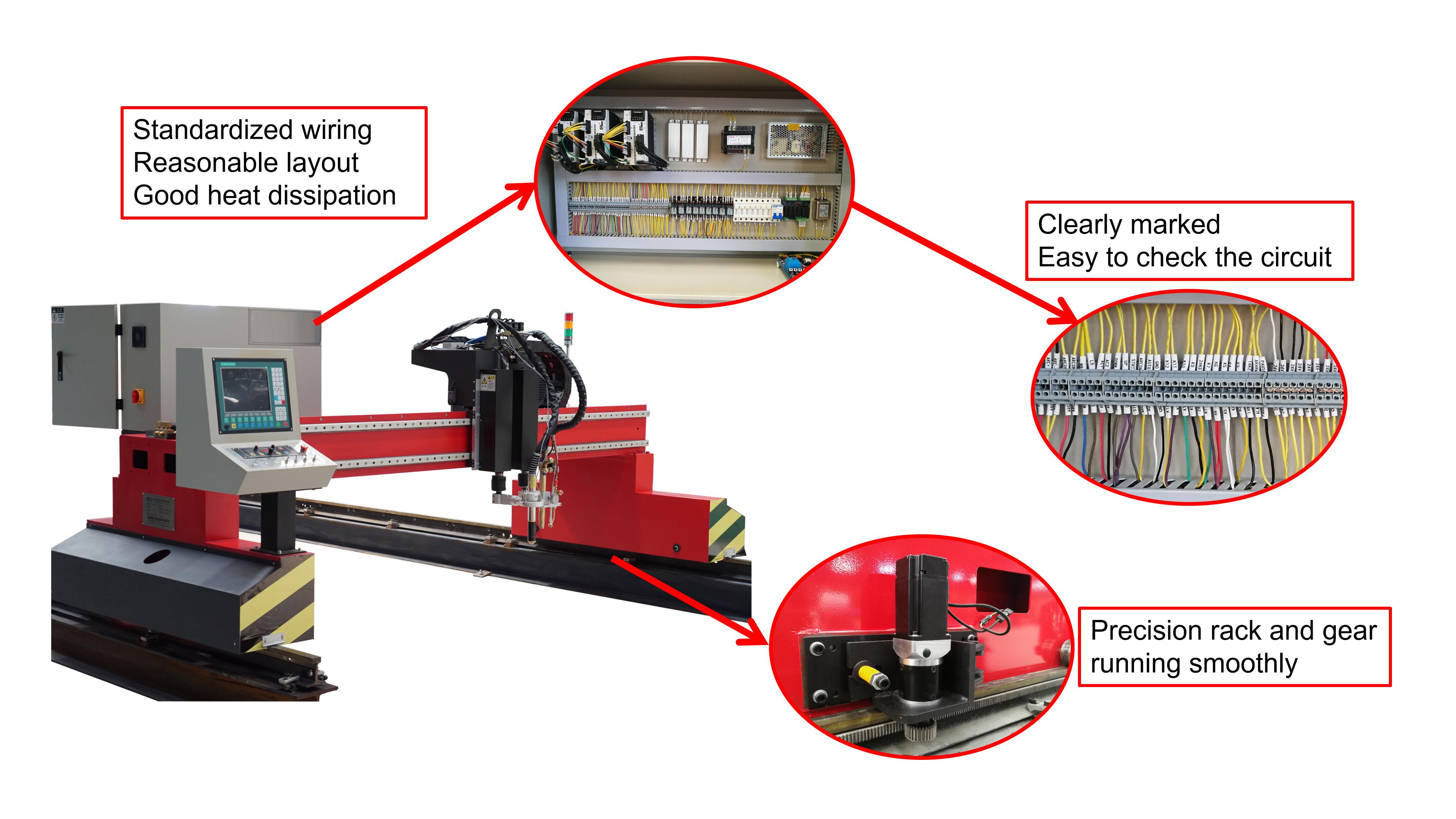

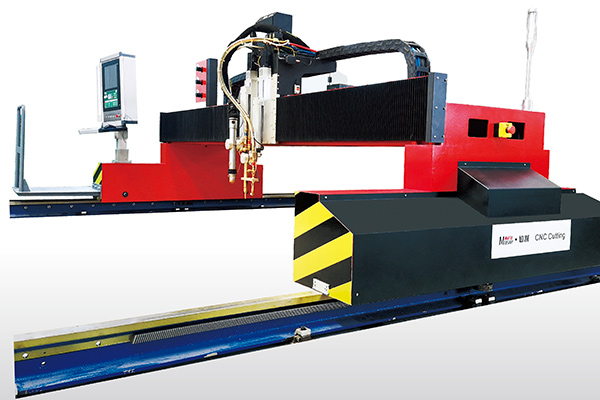

- The whole machine adopts the welded steel plate welded structure. The beam is cut by laser cutting and then welded together. The upper and lower sides of the beam are bent by 90 degrees with the steel plate, which can reduce the deformation and increase the rigidity.

- The beam hanging plate is welded with 20mm steel plate, and the whole surface is processed by gantry planer to reduce the deformation of the whole surface and improve the precision.

- After the whole machine is welded, firstly, the aging treatment is performed after stress aging, followed by the surface rust removal treatment. After the primer is applied, the surface is painted.

Technical parameter

| Model |

MS-4B (5012) |

||

| Machine structure |

Laser cutting, steel plate welding structure with heat treatment |

||

| Effective cutting range(X/Y) |

4000 x 10000mm |

||

| Lateral rail spacing |

5000mm |

||

| Longitudinal guide length |

10000mm |

||

| The number of lifts |

Standard for the double moving lift device |

||

| Input voltage |

AV-220V Single phase AV-220V |

||

| input power |

About 2500W |

||

| Running speed |

0-10000mm/min |

||

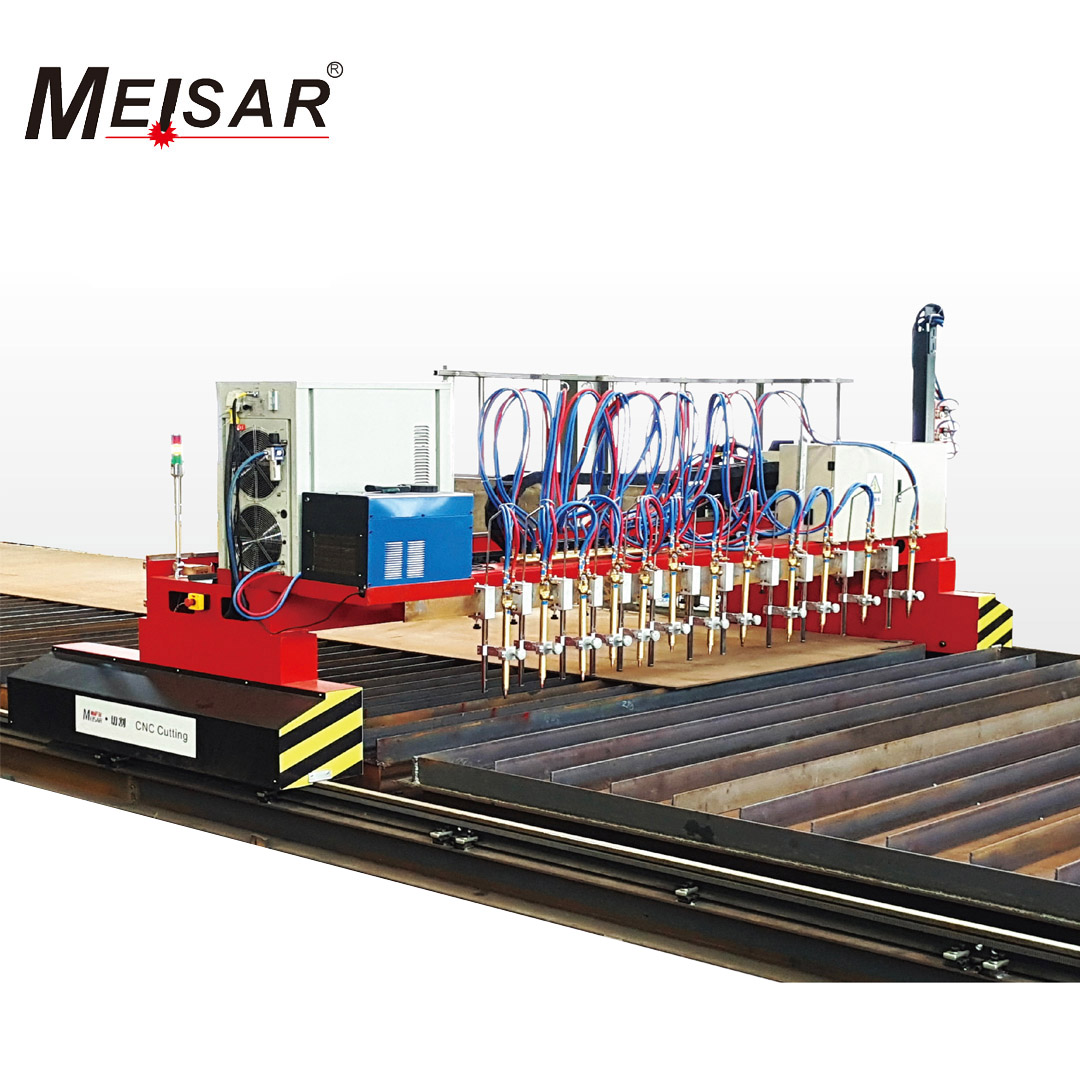

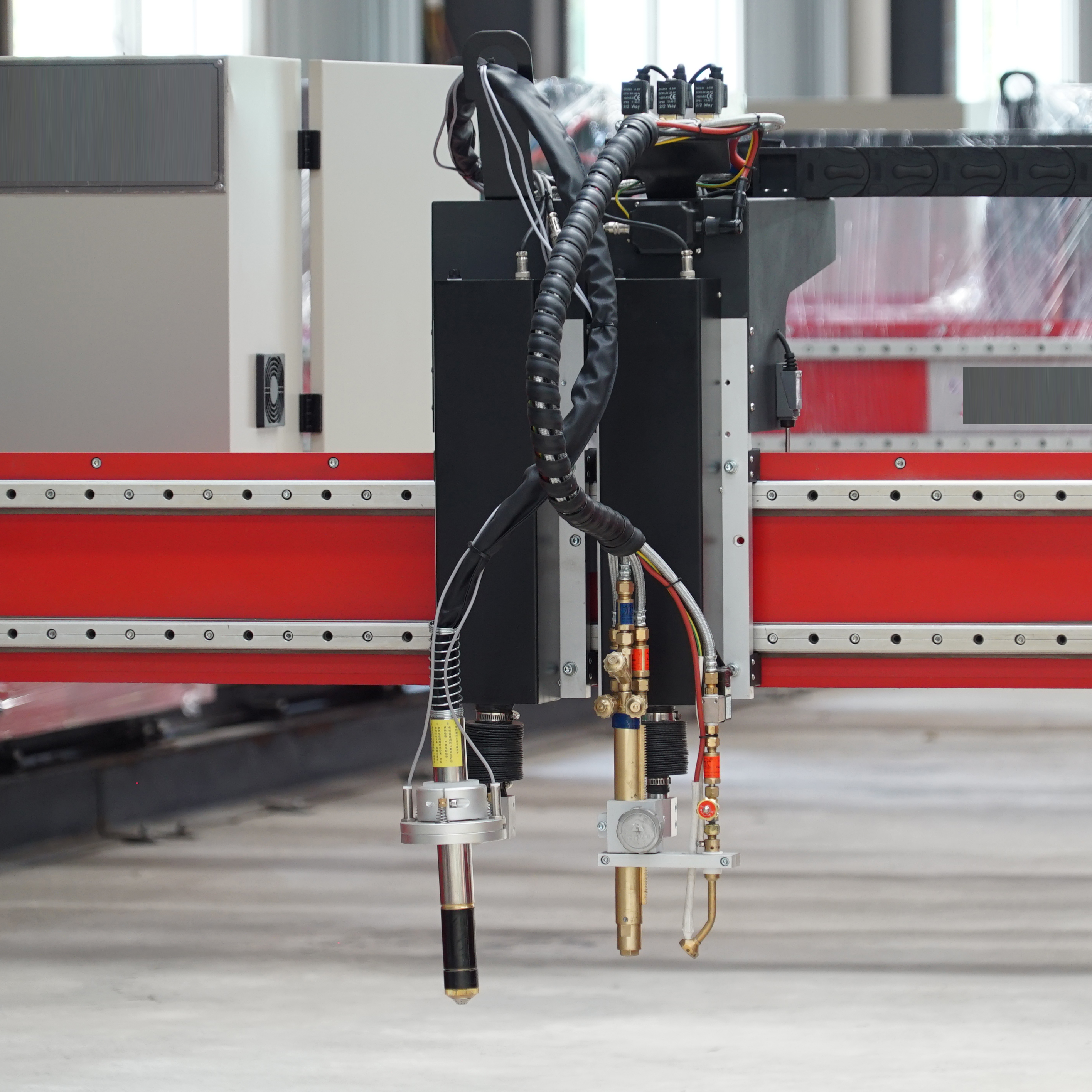

| Cutting type |

1, plasma cutting (with plasma power) 2, flame cutting 3, flame + plasma cutting |

||

| Torch lift |

≤160mm |

||

| Operating accuracy |

0.2mm/m |

||

| Flame cutting thickness |

Piercing thickness: 5-60mm Edge cutting thickness: 5-200mm |

||

| Plasma cutting thickness |

According to the size of the plasma power supply |

||

| Flame automatic Ignition device |

With flame automatic ignition device function |

||

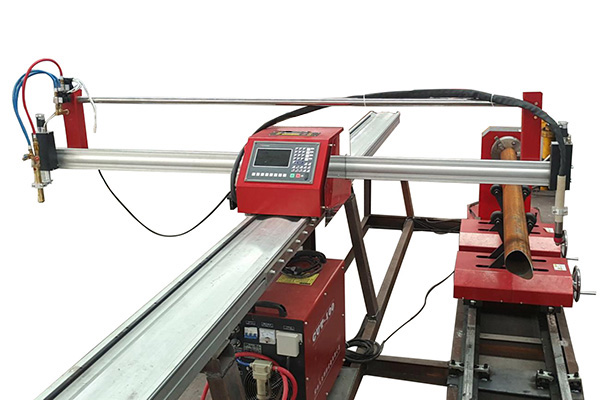

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for 2019 High quality Plate Cutting - MS-4B (5012) Gantry CNC Plasma Cutting Machine – Meisar , The product will supply to all over the world, such as: Southampton, Norway, San Diego, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Write your message here and send it to us