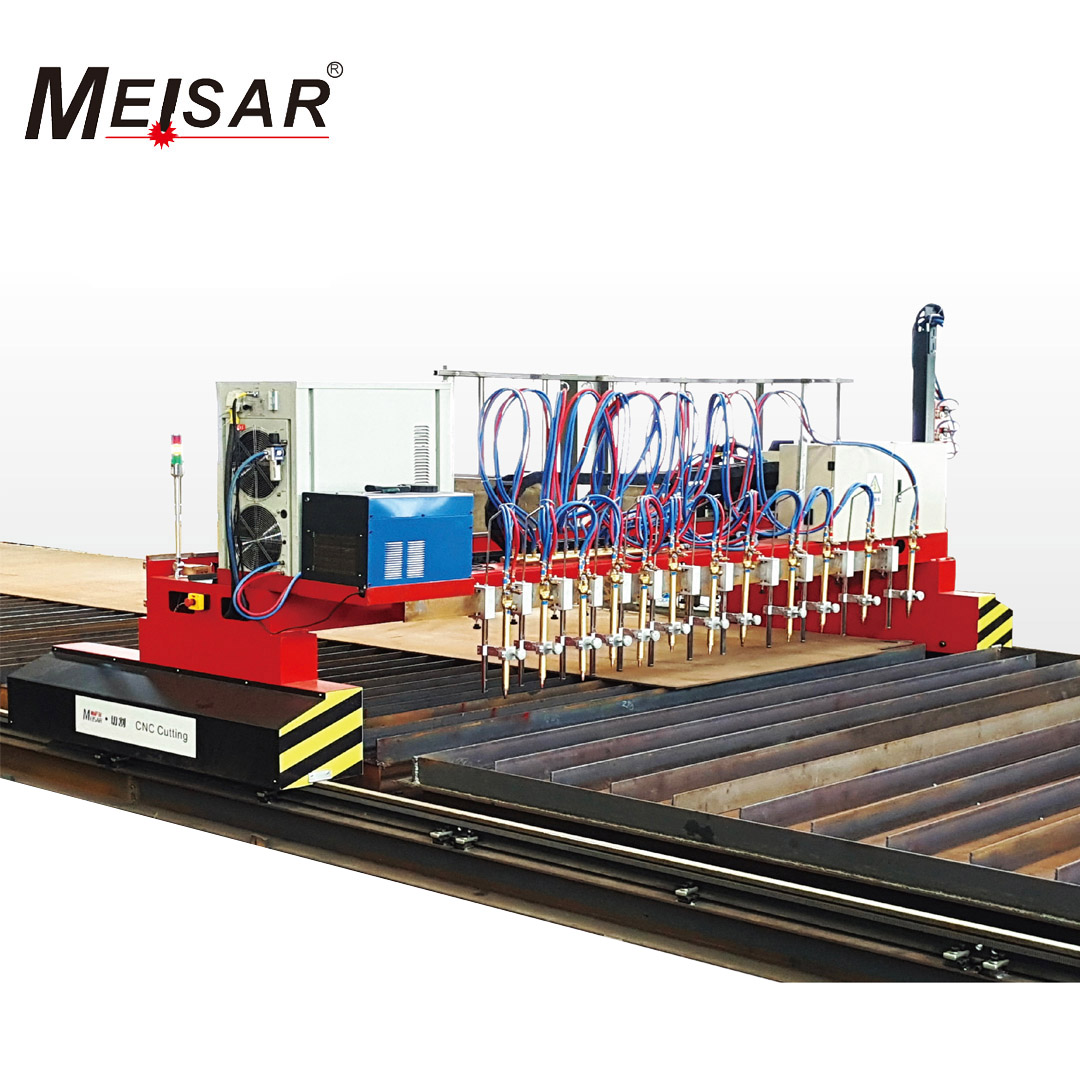

100% Original Cnc Plasma Systems - Industrial desktop CNC plasma cutting machine MODEL MS-1530T – Meisar

100% Original Cnc Plasma Systems - Industrial desktop CNC plasma cutting machine MODEL MS-1530T – Meisar Detail:

The machine configuration

1, the system has automatic bridge, the path to break up, add knife line, automatic positioning and other functions, support PLT, ENG, DXF, G code and other formats.

2, graphics can be any rotation, scaling, X / Y mirror, moments arranged, empty walk, and other functions. Support the processing of pause, forward, backward, high-speed and other functions.

3, automatic seam compensation, the original rail back, forward and other functions. The main features of the device – efficient: the fastest up to 15m / min Stability: the choice of high-quality high-quality components, the top core components. Energy saving: change the traditional backward technology, the equipment cutting workload With the workload of three workers in the workpiece, so as to save you cost.

4, only a few steps can achieve the purpose of cutting

Technical Parameters

| Name |

Industrial desktop CNC piasma cutting machine |

|||||

| Model | MS-1530T | MS-1540T | MS-1560T | MS-1530TX-SE | MS-1540T-SE | MS-1560TX-SE |

| Motor type |

Dual drive 86 # motor + planetary gear reducer |

Dual drive Panasonic servo motor + planetary gear unit |

||||

| Effective cutting range (X/Y) | 1500*3000 | 1500*4000 | 1500*6000 | 1500*3000 | 1500*4000 | 1500*6000 |

| Customize information |

Longitudinal rail length (Y axis) can be extended or shortened according to user requirements |

|||||

| Rail spacing | 2050mm | 2050mm | 2050mm | 2050mm | 2050mm | 2050mm |

| Rail length | 3850mm | 4350mm | 6800mm | 3850mm | 4350mm | 6800mm |

| Torch raise type |

1, plasma arc pressure increase 2, pneumatic control increased |

|||||

| Input voltage |

Single-phase AC-220V (soot cleaning equipment AC-380V) can be customized other voltage |

|||||

| input power |

About 1100W (dust purification equipment about 2200W) |

|||||

| Running speed |

0-10000mm/min |

0-10000mm/min |

||||

| Cutting type |

Plasma arc pressure adjustment Automatic cutting / plasma pneumatic adjustment cutting |

|||||

| Workpiece gas |

Compressed air (0.4Mpa-0.55Mpa) |

|||||

| Emergency stop switch |

Yes |

|||||

| Workpiece ambient temperature |

-5℃/50℃ |

|||||

| Relative humidity |

≤95%不凝结 |

|||||

| transfer method |

Gear rack drive |

|||||

| Torch lift |

≤ 150mm |

|||||

| Operating accuracy |

0.2mm/m |

|||||

| Plasma cutting thickness |

Depending on the size of the plasma power supply |

|||||

| Cutting table infrastructure |

Cutting the host for the one-piece structure, we provide the whole machine, no need to do material |

|||||

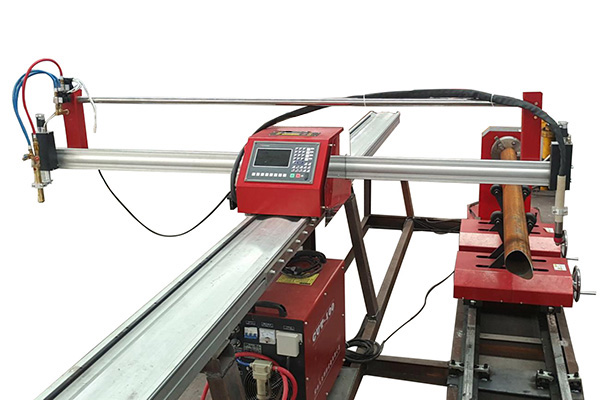

Product detail pictures:

Related Product Guide:

How to choose a CNC plasma cutter

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of 100% Original Cnc Plasma Systems - Industrial desktop CNC plasma cutting machine MODEL MS-1530T – Meisar , The product will supply to all over the world, such as: Slovenia, Mumbai, Cambodia, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.